Aluminum Composite Material (ACM/ACP)

At CladCan, we specialize in high-quality Aluminum Composite Panel (ACP) solutions, catering to a wide range of industries across Ontario. Our ACM panels are trusted by architects, developers, builders, contractors, designers, and engineers, delivering exceptional quality, durability, and versatility for modern construction projects.

We offer a comprehensive selection of premium ACM brands such as ALPOLIC® – ALUBOND® – ALUCOIL® – LARSON® – REYNOBOND® – ALUCOBOND® – ALCOTEX® – ALFREX® in various finishes and colors, ensuring the perfect fit for any architectural vision. Using advanced technology and precision fabrication techniques, we customize ACM panels to your exact specifications—whether for intricate designs or large-scale applications.

With CladCan, you get innovative, reliable, and high-performance ACM solutions designed to elevate your projects. Let’s build something extraordinary together!

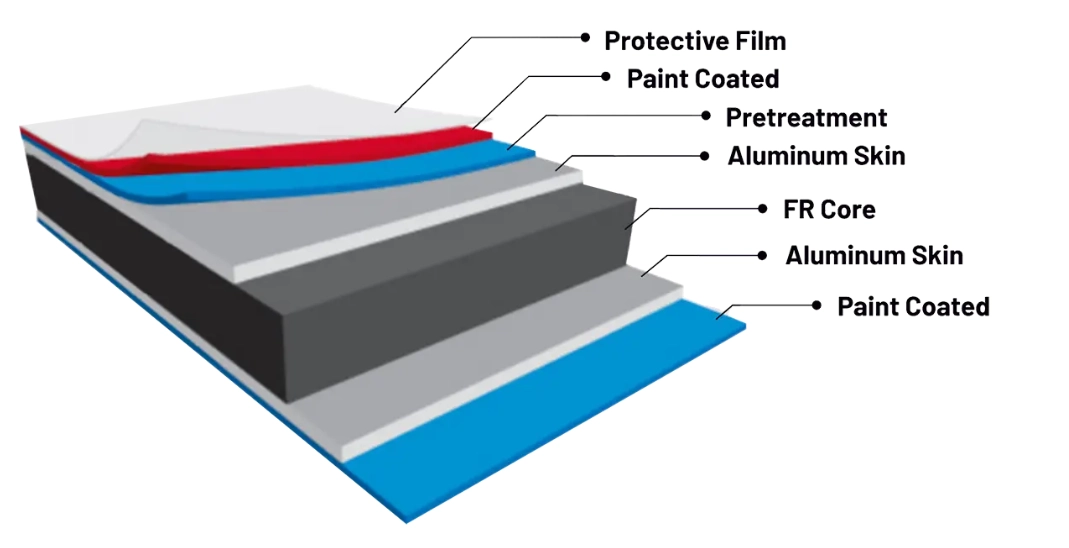

Aluminum Composite Panels (ACP/ACM) are modern building materials made of two thin layers of aluminum enclosing a non-aluminum core, typically made from materials like polyethylene or mineral-filled materials. This unique construction combines the strength and durability of aluminum with the lightweight properties of composite materials, making ACP an ideal choice for a wide range of applications.

There are various types of ACP/ACM available on the market, including fire-rated panels (which meet strict fire safety standards), non-combustible panels (for enhanced safety), and decorative panels (available in various colors and finishes). Each type serves specific needs, enabling architects and builders to select the most appropriate option for their projects.

ACM panels consist of three primary layers:

- Outer Aluminum Layers: Two sheets of aluminum form the outer layers, which can be finished with various coatings (e.g., PVDF, polyester) to enhance durability and aesthetic appeal. The thickness typically ranges from 0.5 mm to 1.5 mm, ensuring structural integrity.

- Core Material: The core is either polyethylene (PE) for standard applications or mineral-filled (FR) for fire-resistant options, striking a balance between lightweight properties and strength.

- Bonding Process: Advanced adhesive technology is used to bond the layers, creating a solid composite structure that leverages the benefits of aluminum and the core material.

Choosing ACM comes with numerous benefits:

Cost-Effectiveness: While the initial investment in ACPs may be competitive, their low maintenance costs and durability translate into significant long-term savings. Their energy efficiency can also lead to reduced heating and cooling costs, further enhancing their value.

Cost-Effectiveness: While the initial investment in ACPs may be competitive, their low maintenance costs and durability translate into significant long-term savings. Their energy efficiency can also lead to reduced heating and cooling costs, further enhancing their value.

Durable & Long-Lasting: ACPs are designed to withstand harsh environmental conditions, including extreme weather, UV radiation, and corrosion. Their robust nature ensures that they maintain their appearance and structural integrity over time, making them a reliable choice for both exterior and interior applications.

Durable & Long-Lasting: ACPs are designed to withstand harsh environmental conditions, including extreme weather, UV radiation, and corrosion. Their robust nature ensures that they maintain their appearance and structural integrity over time, making them a reliable choice for both exterior and interior applications.

Aesthetic Versatility: ACPs come in a wide array of colors, finishes (including matte, gloss, and metallic), Woodgrain, and textures, allowing designers to achieve various aesthetic effects. They can mimic the appearance of more expensive materials like wood or stone, providing a cost-effective solution without compromising visual appeal.

Aesthetic Versatility: ACPs come in a wide array of colors, finishes (including matte, gloss, and metallic), Woodgrain, and textures, allowing designers to achieve various aesthetic effects. They can mimic the appearance of more expensive materials like wood or stone, providing a cost-effective solution without compromising visual appeal.

Lightweight: Weighing significantly less than traditional materials like solid aluminum or stone, ACPs facilitate easier handling and faster installation. This lightweight characteristic also reduces the structural load on buildings, allowing for more versatile architectural designs.

Lightweight: Weighing significantly less than traditional materials like solid aluminum or stone, ACPs facilitate easier handling and faster installation. This lightweight characteristic also reduces the structural load on buildings, allowing for more versatile architectural designs.

Fire Resistance Options: We offer ACM products with fire-rated cores, ideal for applications that require enhanced fire safety.

Fire Resistance Options: We offer ACM products with fire-rated cores, ideal for applications that require enhanced fire safety.

Low Maintenance: Cleaning is simple, and our panels resist stains and fading, allowing you to maintain their appearance with ease.

Low Maintenance: Cleaning is simple, and our panels resist stains and fading, allowing you to maintain their appearance with ease.

Sustainability: Many ACPs are made from recyclable materials and can be recycled at the end of their life cycle. Their energy efficiency and durability contribute to sustainable building practices, making them an environmentally friendly choice for modern construction.

Sustainability: Many ACPs are made from recyclable materials and can be recycled at the end of their life cycle. Their energy efficiency and durability contribute to sustainable building practices, making them an environmentally friendly choice for modern construction.

ACM is suitable for a variety of applications, and at CladCan, we cater to:

Commercial Buildings: Ideal for exterior cladding, ACM gives a contemporary look to office spaces, shopping malls, and hospitality venues.

Residential Projects: Our panels can enhance the facade and interiors of homes, adding both style and protection.

Industrial Uses: Factories and warehouses benefit from ACM’s strength and low maintenance needs for wall and roof cladding.

Public Infrastructure: Airports, hospitals, and educational institutions utilize ACM for both functional and aesthetic improvements.

Signage: Perfect for creating striking signage that stands the test of time.

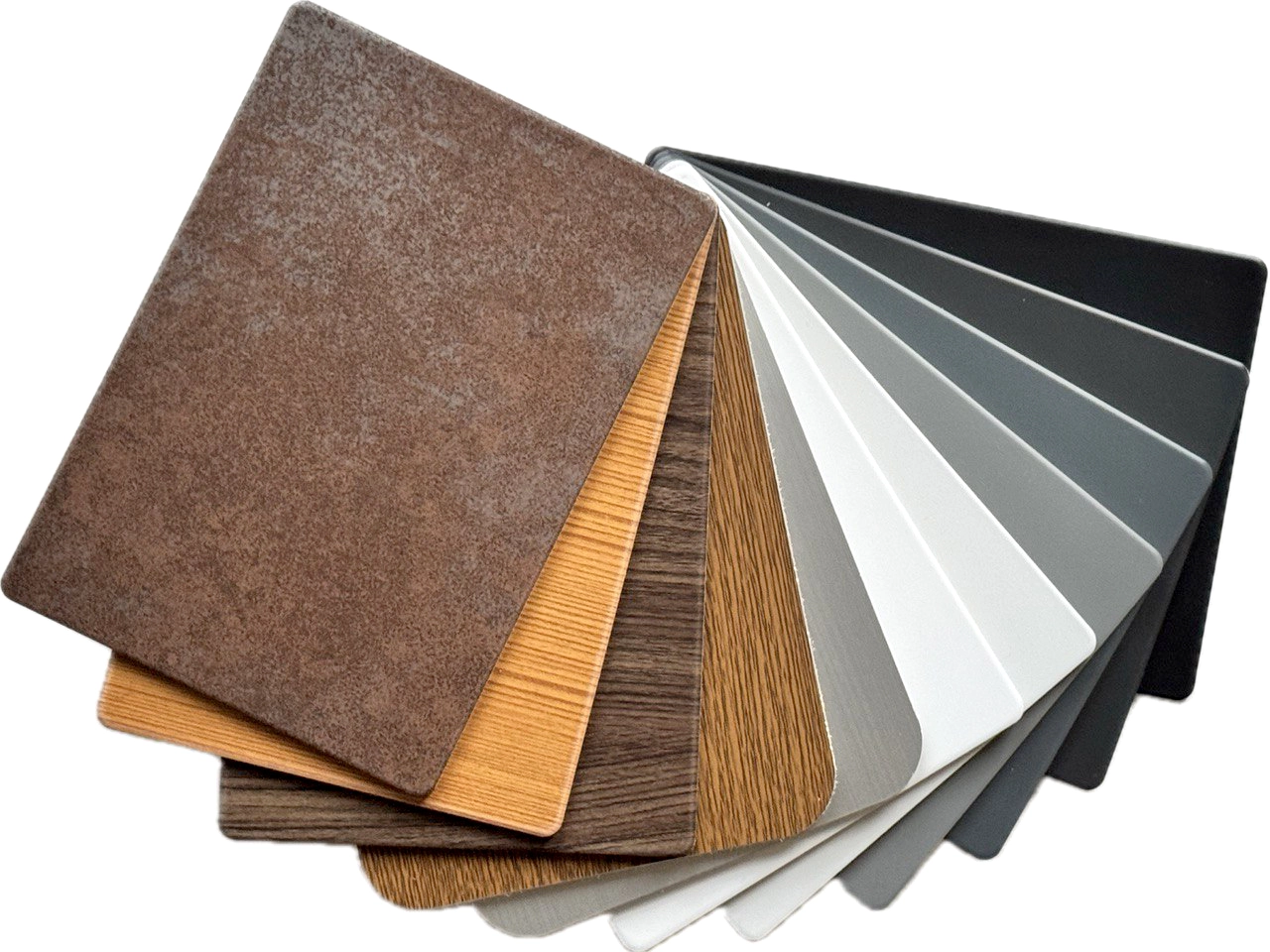

At CladCan, we believe that design should never be limited. That’s why we offer a wide selection of premium finishes and colors for our Aluminum Composite Material (ACM) panels, allowing you to bring your architectural vision to life with style and precision.

Why Choose Our ACM Finishes?

✔ Vibrant & Durable – Fade-resistant colors that stand the test of time.

✔ Weather & UV Resistant – Built to withstand the elements without losing appeal.

✔ Customizable Options – Tailor-made finishes to match your unique project needs.

✔ Seamless Integration – Perfect for facades, signage, interiors, and more.

At CladCan, we don’t just provide ACM panels—we deliver design freedom and lasting quality.

Explore a World of Possibilities

Standard Solid Colors

For a clean, contemporary look, our solid color options offer timeless appeal. These hues range from classic whites and grays to bold reds, blues, and blacks, ensuring seamless integration with any design.

Metallic & Brushed Finishes

For a sleek, high-end aesthetic, our metallic and brushed finishes mimic the appearance of natural metals like aluminum, bronze, or stainless steel while maintaining the lightweight benefits of ACM. These finishes add a sophisticated, modern touch to any façade.

Woodgrain Finishes

Enjoy the warmth of natural wood without the maintenance. Our woodgrain ACM panels replicate the texture and look of real wood in various tones, including oak, walnut, and teak. Perfect for both contemporary and traditional designs.

Stone & Textured Finishes

If you’re looking for the elegance of stone or concrete, our stone-textured ACM panels provide a realistic appearance while being lightweight and easy to install. These finishes are ideal for adding depth and character to exterior and interior spaces.

Custom Colors & Finishes

We understand that every project is unique. That’s why we offer custom color-matching services to achieve your exact design vision. Whether you need corporate branding colors or a specific shade to match existing elements, we can create a tailored solution.

Discover the perfect finish for your project today!

Our ACM panels are available with the following specifications:

- Panel Thickness: Typically between 3 mm and 6 mm.

- Weight: Approximately 3 to 6 kg/m², depending on the thickness and core type.

- Fire Rating: Options include Class B for non-combustible cores.

- Standard Sizes: Available in sizes such as 62” x 144”, and 62” x 196” with custom sizes upon request.

- Finish Options: PVDF, polyester, anodized, and custom finishes.

- Warranty: We offer warranties ranging from 5 to 20 years, ensuring confidence in your investment.

At CladCan, our ACM fabrication process includes:

Precision Cutting: Utilizing CNC machines and water jet cutting for accurate panel sizes.

Precision Cutting: Utilizing CNC machines and water jet cutting for accurate panel sizes.

Routing and Finishing: Edges are routed for smooth finishes, and panels undergo rigorous quality control.

Routing and Finishing: Edges are routed for smooth finishes, and panels undergo rigorous quality control.

Drilling for Fastening: Holes are drilled as per design specifications, ensuring secure installation.

Drilling for Fastening: Holes are drilled as per design specifications, ensuring secure installation.

Quality Control: Each panel is inspected for defects, ensuring consistent quality and compliance with specifications.

Quality Control: Each panel is inspected for defects, ensuring consistent quality and compliance with specifications.

Key components we provide include:

Extrusions: Essential for framing and support, our aluminum extrusions ensure a robust structure for ACM panels.

Rivets and Clips: Available in various sizes, these components secure panels and provide flexibility for temperature changes.

We provide multiple fastening systems for your ACM panels:

Mechanical Fasteners: Screws, rivets, and bolts for secure attachment.

Clip Systems: Allow for expansion while securely holding panels in place, ideal for ventilated facades.

The comprehensive process at CladCan includes:

Design Consultation: We collaborate with clients to develop designs that meet both aesthetic and functional needs.

Design Consultation: We collaborate with clients to develop designs that meet both aesthetic and functional needs.

Panel Layout and Field Measurement: Accurate layout planning and on-site measurements ensure a perfect fit.

Panel Layout and Field Measurement: Accurate layout planning and on-site measurements ensure a perfect fit.

Shop Drawings: Detailed drawings are created for approval, showcasing dimensions and fastening details.

Shop Drawings: Detailed drawings are created for approval, showcasing dimensions and fastening details.

Fabrication: Panels are fabricated according to specifications, with a focus on quality control.

Fabrication: Panels are fabricated according to specifications, with a focus on quality control.

Delivery: At CladCan, we ensure the safe and timely delivery of fabricated ACM panels directly to your job site. Our reliable logistics team coordinates every shipment with precision, ensuring your panels arrive on schedule and in perfect condition, ready for installation.

Delivery: At CladCan, we ensure the safe and timely delivery of fabricated ACM panels directly to your job site. Our reliable logistics team coordinates every shipment with precision, ensuring your panels arrive on schedule and in perfect condition, ready for installation.

Installation: Our expert teams handle installation with precision. The installation process typically involves supply and installation of the following:

Installation: Our expert teams handle installation with precision. The installation process typically involves supply and installation of the following:

Weather Resistive Barrier (WRB) Installation: A layer of Weather resistive membrane such as Blueskin® or Tyvek® House wrap mounted on the existing sheathing to protect the structure from the elements and prevent molds.

Insulation boards: A layer of Semi-rigid or Rigid insulation boards against the sheathing to enhance thermal performance and improve energy efficiency.

Strapping Installation: A Wood or Metal mesh is constructed to ease the Airflow, Plumb the wall and support the panels.

Metal Flashing: A metal flashing with drip-edge is mounted on the Doors & Windows headers and transitional sections to prevent water infiltration from vulnerable areas.

Panel Attachment: ACPs are securely attached to the strapping using appropriate fasteners and thermal break Clips.

Project Management: Throughout the process, our project management team ensures timelines are met and communication remains clear with the client, all related trades, and PMs.

Project Management: Throughout the process, our project management team ensures timelines are met and communication remains clear with the client, all related trades, and PMs.

Completion and Support: We conduct final inspections to ensure satisfaction and provide ongoing support for maintenance and inquiries.

Completion and Support: We conduct final inspections to ensure satisfaction and provide ongoing support for maintenance and inquiries.

Cleaning Tips: Regular cleaning with mild soap and water is recommended to maintain the panels' appearance. Avoid abrasive cleaners that could scratch the surface. For tough stains, a diluted vinegar solution can be effective.

Maintenance Schedule: Inspect ACPs at least twice a year for signs of damage or wear, especially after severe weather. Address any issues promptly to prevent further damage.

What is the lifespan of ACP/ACM? Typically, ACPs have a lifespan of 20-30 years, depending on the quality of the material and environmental conditions.

Is ACP fire-resistant? Many ACPs are available in fire-rated options that meet stringent fire safety standards, making them suitable for various applications.

Can ACP be painted or coated? Yes, ACPs can be painted or coated, but it’s essential to use compatible products and follow manufacturer guidelines to ensure adhesion and longevity.

How does ACP compare to other cladding materials? ACPs offer a unique combination of lightweight durability, aesthetic flexibility, and cost-effectiveness compared to traditional materials like brick or stone.

What are the warranty terms for ACP products? Warranty terms vary by manufacturer, but most ACP products come with a 10- to 20-year warranty covering defects in materials and workmanship.

By choosing CladCan, you partner with a trusted provider of exterior siding and cladding services throughout Ontario. Our commitment to quality, attention to detail, and customer satisfaction sets us apart in the industry. We are dedicated to delivering solutions that not only meet but exceed your expectations, ensuring your projects stand out for their quality and design.

Get Started Today!

Ready to enhance your project with high-quality Aluminum Composite Panels? Contact CladCan today for a free consultation or to request samples. Let us help you bring your vision to life with our premium ACM solutions!